The global die casting market is estimated to be valued at USD 77.99 billion in 2023 and is expected to exhibit a CAGR of 6.24% over the forecast period of 2023-2028, as highlighted in a new report published by Coherent Market Insights.

- A) Market Overview:

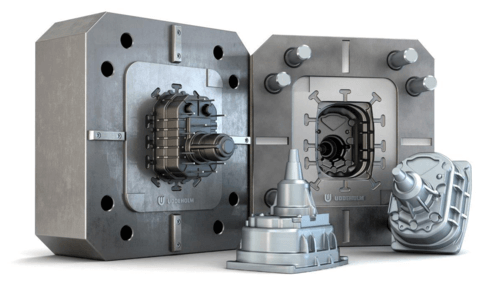

Die casting is a manufacturing process used to produce metal parts by forcing molten metal into a mold cavity. It is a cost-effective method for producing complex shapes with high dimensional accuracy and smooth surface finish. Die casting offers various advantages such as fast production rates, high volume production, and good surface finish. The increasing demand for lightweight and fuel-efficient vehicles is driving the growth of the die casting market.

- B) Market Key Trends:

One key trend in the global die casting market is the growing demand from the automotive industry. The automotive sector is the largest end-user of die castings, primarily for the production of engine parts, transmission parts, and structural components. With the increasing focus on reducing vehicle weight and improving fuel efficiency, die casting is playing a crucial role in the automotive manufacturing process. For example, aluminum die castings are widely used in the production of lightweight body structures, which help in reducing overall vehicle weight and improving fuel economy.

- C) Porter’s Analysis:

Threat of new entrants: The die casting market requires significant capital investment and specialized knowledge, which acts as a barrier to new entrants. Established players have a strong foothold in the market, making it difficult for new players to enter.

Bargaining power of buyers: Buyers in the die casting market have moderate bargaining power due to the presence of multiple suppliers. However, buyers with large order volumes may have a higher bargaining power and can negotiate better prices.

Bargaining power of suppliers: Suppliers in the die casting market have moderate bargaining power due to the availability of alternative suppliers. However, suppliers with unique capabilities and specialized expertise may have a higher bargaining power.

Threat of new substitutes: The threat of new substitutes in the die casting market is low. Die casting offers several advantages over alternative manufacturing processes such as high production rates, dimensional accuracy, and good surface finish, making it the preferred choice for many industries.

Competitive rivalry: The Die Casting Market is highly competitive, with key players focusing on product innovation, expanding their production capacities, and entering into strategic partnerships to gain a competitive edge. The market is consolidated, with several large players dominating the market.

- D) Key Takeaways:

– The global die casting market is expected to witness high growth, exhibiting a CAGR of 6.24% over the forecast period, due to increasing demand from the automotive industry.

– Regional Analysis: Asia Pacific is the fastest-growing and dominating region in the die casting market, owing to the presence of a large automotive manufacturing industry in countries like China and India. Europe and North America are also significant contributors to the market.

– Key Players: Key players operating in the global die casting market include Alcast Technologies, Arconic, Consolidated Metco, Inc., Dynacast International Inc., Gibbs Die Casting, Ryobi Die Casting Inc., Bodine Aluminum, Martinrea Honsel Germany GmbH, Leggett & Platt, Endurance Technologies Ltd., Empire Die Casting Company, Alcoa Inc., Hitachi Metals Ltd, Nemak S.A.B. de C.V., GF Casting Solution AG, Shiloh Industries Inc., Rheinmetall Automotive AG, Sigma Electric Manufacturing Corp., Pace Industries, and Guangdong Yizumi.

In conclusion, the global die casting market is poised for high growth due to the increasing demand from the automotive industry. With the automotive sector focusing on lightweight and fuel-efficient vehicles, the use of die casting is expected to grow, further driving the market’s expansion.