Motor control centers (MCCs) play a crucial role in providing reliable electric power and control in industrial facilities. As industrial processes become more automated and complex, low voltage MCCs are essential for safely distributing and controlling power to motors, equipment, and other loads. In this article, we will explore the components, functions and benefits of low voltage MCCs.

What is a Low Voltage Motor Control Center?

A Low Voltage Motor Control Center (LV MCC) is a metal enclosed assembly of one or more enclosed sections having a common power bus and principally containing motor control units. LV MCCs operate at 600 volts or less and are used to provide power distribution and motor control/protection for industrial machinery and processes.

The main components include:

– Power bus – The common power bus distributes power throughout the MCC sections from the incoming service or transformers. It provides a metal enclosure for conductors.

– Sections – Individual sections house motor controllers, protective devices, metering equipment and related components. Sections can be added or removed as needed.

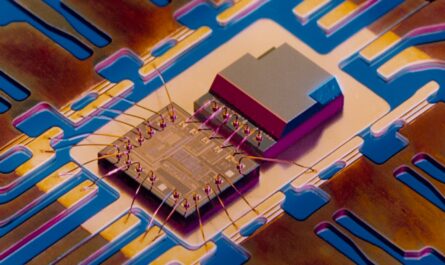

– Motor controllers – These include circuit breakers, starters, variable frequency drives and other devices to safely start, stop, protect and control individual motors or loads.

– Monitoring/controls – Modern LV MCCs incorporate computerized controls, HMIs, PLCs and other electronics for remote monitoring and automated control.

Key Functions of an LV MCC

Power Distribution

– LV MCCs distribute power safely and reliably from the main power source to individual motors, machines and process loads located throughout a plant facility.

Motor Protection and Control

– Controllers provide overload, short circuit and other protections for motors. Starters, VFDs and other devices safely start/stop motors and control motor speed as needed.

Sectionalize Power Interruption

– Faults can be isolated to individual sections without disrupting power to the entire MCC, minimizing downtime for maintenance or repairs.

Monitoring and Integration

– Section-based metering and controls allow remote or automated monitoring and control of energy usage, equipment status, process sequences and more. LV MCCs easily integrate with plant SCADA, HMIs and process control systems.

Flexibility and Scalability

– Modular design allows sections to be added or removed as needed over time to support new equipment or process changes without requiring expensive upgrades to the entire power distribution system.

Benefits of Using Low Voltage MCCs

Reliability

– LV MCCs provide a reliable single-point power source without overloading switches or circuit breakers. The isolated bus configuration improves reliability over dispersed motor control designs.

Safety

– Enclosures isolate live components from human contact and short circuit hazards are contained within each section for increased worker safety. Arc flash risks are reduced compared to panel boards.

Energy Efficiency

– Soft starting, variable speed control and integrated drives optimize motor/load efficiency. Section-level metering enables usage monitoring to minimize waste.

Lifecycle Cost Savings

– Modularity reduces installation and future upgrade costs compared to rewiring panels or switchgear. Overall ownership costs are lower over the typical 30-40 year lifespan of an LV MCC.

Process Uptime

– Fault isolation capabilities keep downtime to a minimum for repairs or maintenance compared to alternatives without bus segmentation. Production disruptions are limited.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it