The North America Hydraulic Fluid Connectors Market is estimated to be valued at US$ 5.3 Bn or Mn in 2023 and is expected to exhibit a CAGR of 8.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

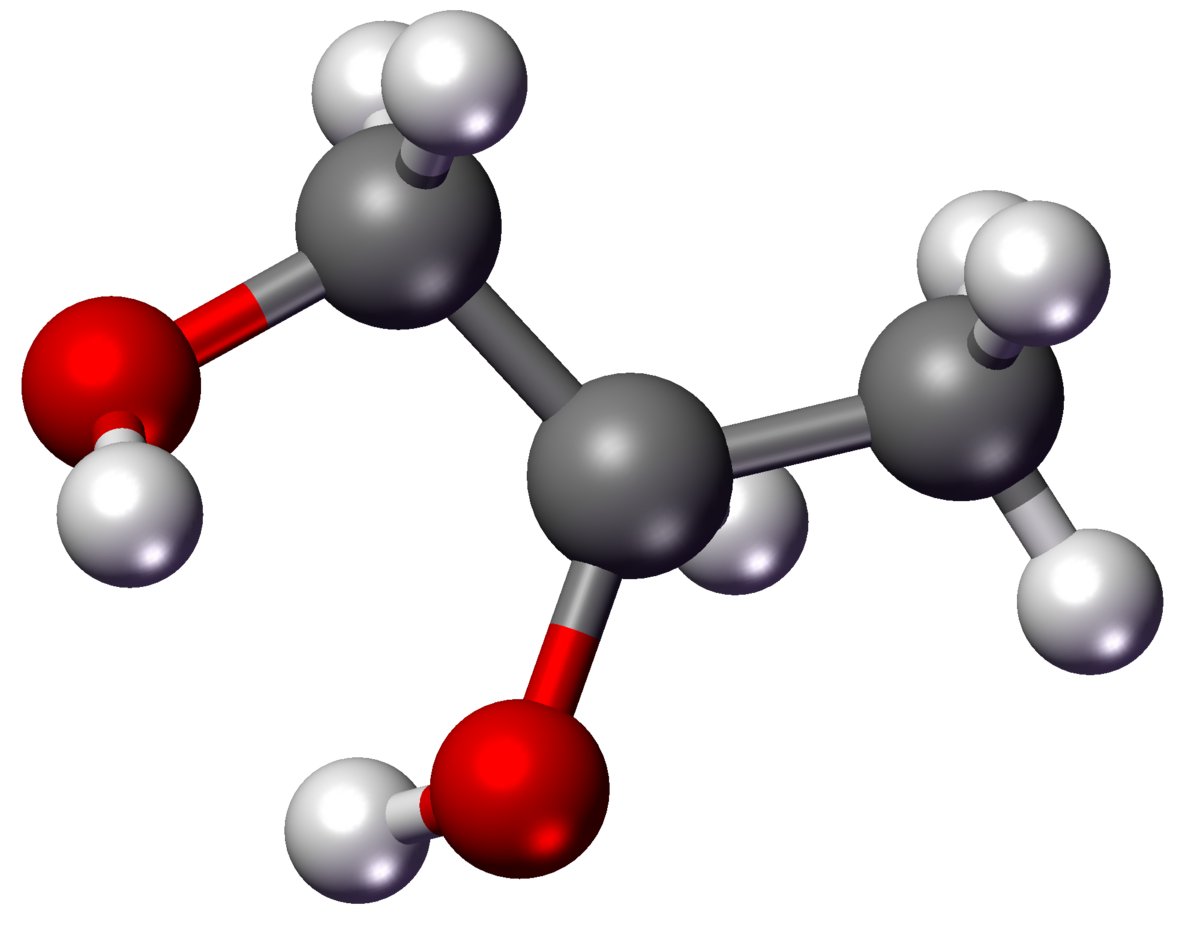

Hydraulic fluid connectors are used in various industrial and automation equipment for transferring hydraulic fluid between hydraulic components and equipments. They are utilized in wide range of equipment such as construction machinery, material handling equipments, agricultural machinery, oil & gas equipment and others. Hydraulic fluid connectors ensure safe, secure and leak proof hydraulic fluid transmission between different components of equipment.

Market Dynamics:

Increasing construction activities in the region is a key driver fueling the growth of North America hydraulic fluid connectors market. Rapid urbanization and infrastructure development projects are increasing the demand of construction machinery and equipment which in turn is augmenting the adoption of hydraulic fluid connectors. Furthermore, growing adoption of automation technology across various end use industries is also boosting the market growth. Material handling equipments utilized widely across industries require hydraulic fluid connectors for operation. However, availability of alternative material for manufacturing connectors and fluctuation in raw material prices may hamper the market growth over the forecast period.

Segment Analysis

The North America hydraulic fluid connectors market is dominated by the threaded connectors sub-segment. Threaded connectors have high resistance to vibration and temperature fluctuations which make them suited for heavy-duty industrial machinery and off-highway vehicles operating in harsh environments. Their rugged and durable design allow them to withstand high pressure and turbulence within hydraulic circuits for long periods of time.

PEST Analysis

Political: Regulations regarding environmental protection and emission standards in countries like the US and Canada are driving demand for more efficient hydraulic systems and components.

Economic: Growth of end-use industries such as construction, mining, agriculture, and transportation is supporting the growth of the hydraulic systems market and subsequent demand for connectors in the region.

Social: Rising consumer preference for fuel-efficient and eco-friendly vehicles is increasing the adoption of advanced hydraulic technologies.

Technological: Developments in material science are allowing manufacturers to develop connectors with better pressure handling capability, corrosion resistance and leak-proof properties. Introduction of smart connectivity features is also gaining traction.

Key Takeaways

The North America Hydraulic Fluid Connectors Market Size is expected to witness high growth, exhibiting CAGR of 8.6% over the forecast period, due to increasing use of heavy construction machinery and commercial vehicles in industries such as mining, construction, agriculture, and transportation.

Regional analysis: North America dominates the global hydraulic fluid connectors market primarily due to high demand from the well-established construction, mining, agriculture, aviation and transportation industries in the US and Canada. The US accounted for around 80% of the market share in the region in 2023.

Key players: Key players operating in the North America Hydraulic Fluid Connectors market include Cameron International Corporation, Eaton Corporation Plc., Gates Corporation, Parker Hannifin Corporation, Manuli Hydraulics, Kurt Hydraulics, RYCO Hydraulics pty. Ltd., ITI Corporation, and SPX Corporation. These players focus on new product launches and innovations to cater to diverse application requirements and gain competitive edge. For instance, in 2022, Parker launched advanced O-ring face seal connector series with vibration and pressure resistance up to 5000 PSI for mobile off-highway equipment.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it