Polyvinyl chloride (PVC) pipes have become one of the most widely used piping materials for transporting water in homes and buildings. Known for their sturdiness, affordability and ease of installation, PVC pipes have revolutionized the plumbing and water distribution industries over the past several decades. This article provides an overview of PVC pipes, their uses, advantages and manufacturing process.

Uses of PVC Pipes

PVC pipes find widespread applications in plumbing, sewage, irrigation and other areas that require transport of water or other fluids. Some key uses of PVC pipes include:

– Plumbing: PVC pipes are the most common material used for water supply lines and drain-waste-vent (DWV) systems in residential and commercial buildings. Their corrosion resistance and longevity make them ideal for potable water distribution.

– Sewage: Rigid and flexible PVC Pipes Demand are extensively used to transport wastewater from homes and buildings to municipal sewage systems. Their resistance to degradation ensures wastewater flows safely.

– Irrigation: PVC pipes are a top choice for irrigation of farms, golf courses, parks and other large landscaped areas as they can withstand outdoor environmental conditions and last for decades with minimum maintenance.

– Industrial: Various industries use PVC pipes to transport chemicals, slurries, compressed air and other fluids where corrosion resistance is important. Industries include oil and gas, mining, food processing, manufacturing etc.

Durability: PVC pipes are incredibly durable and can withstand pressures up to 250 PSI. Properly installed PVC systems can last 50-100 years with little maintenance.

– Corrosion resistance: PVC does not corrode, rust or decay when exposed to various fluids like water, chemicals, soils, salt etc. making it suitable for harsh environments.

– Lightweight: PVC is a lightweight material, making pipes easy to transport and install. This also reduces infrastructure costs.

– Low installation costs: PVC pipes are inexpensive and can be joined using affordable and simple mechanical fittings like glue or rubber gaskets, reducing labor costs.

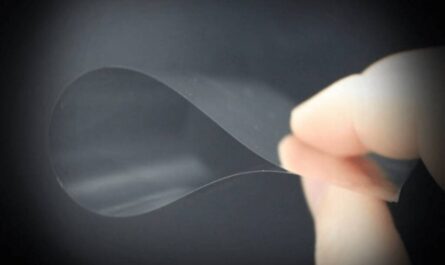

– Strength: PVC pipe walls are thick yet flexible, enabling them to withstand impact, vibrations and ground movement better than metal or clay pipes.

– Chemical resistance: PVC stands up well to exposure from chemicals, being compatible with potable water, wastewater, and many industrial process fluids.

– Noise reduction: PVC pipes provide excellent sound insulation, helping reduce noise transmissions through piping systems. This is a plus for plumbing, sewage system etc.

Manufacturing Process

PVC pipes are made through an extrusion process where PVC resin is softened using heat and forced through a die to form the pipe shape. Here are the key manufacturing steps:

– Resin: The basic raw material is PVC resin which is produced by polymerization of vinyl chloride monomer. Additives are mixed in to improve properties.

– Mixing: The mixer blending equipment heats and mixes the resin with additives uniformly to obtain a homogenous compound. Fillers are also added.

– Extrusion: The compounded material is softened using heat and forced through a die by a screw mechanism into the desired cross-sectional pipe shape under pressure.

– Sizing: As it exits the die, the hot pipe passes through a water bath to cool and size it precisely to required diameter and thickness specifications.

– Cutting and bundling: Extruded pipes are cut to desired lengths, inspected for quality, labeled and packed in bundles for shipping to distributors, fabricators or end users.

– Fabrication: At job sites, pipes are cut, threaded, solvent-welded or joined with mechanical fittings for assembly into the final piping system.

Evolution and Outlook

Since its commercial introduction in the 1930s, PVC piping has evolved significantly. Advances in resin formulation, compounding, extrusion and joining technologies have enhanced properties like strength, durability and chemical resistance of modern PVC pipes. Going forward, PVC is expected to continue finding new applications, driven by its sustainability credentials, recyclability and outstanding value proposition versus competing materials. PVC will likely maintain its preeminent position as the piping material of choice for water, sewage and general fluid handling applications globally.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it